How is the jewelry we wear made? As a jewelry source custom factory, today to friends a complete reveal the whole process of jewelry production!

💡Design

Design:The designer will sketch the new work on paper, and use pencil and gouache to complete the design sketch.This process is less than a few days and a half months, more than a few months, the design details are often repeatedly modified, the design process, the need to consider aesthetics, moral, processability and other factors.

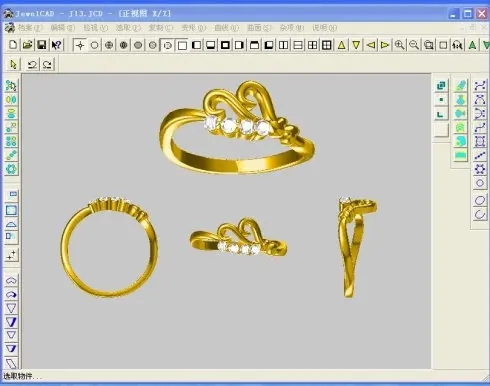

💡Waxed mould making

Waxed plate making: 3D designer according to the design drawings, computer modeling or artisans according to the design drawings by hand engraving wax plate. The wax plate must be smooth and traceless, the structure of each part is reasonable, and the location and size of the gemstone are accurate. (Depending on the complexity of the process, it can be as little as a day or two or as many as a few days.

💡Inverted mold

Inverted mold:Usually using the lost wax casting method, the wax mold into an 18K ring.If it is mass production, then the front wax plate will be made into a daguerreotype pressed into a film, mass production of wax mold.

Specific process:

- Plant wax trees:Multiple wax molds are welded to a wax rod to form a large tree, ready for casting.

- Plaster injection:The planted wax tree and the chassis are put on a stainless steel cylinder together, and the corresponding weight of gypsum slurry is injected along the inner wall of the cylinder until the wax tree is complete. After vacuum pumping by the machine, it is placed for 6-12 hours naturally, waiting for the gypsum to solidified ⌛️

- Baking plaster:Baking plaster mold, dewaxing.

- Casting:Take out the baked plaster mold, prepare the molten metal solution, and inject it through the nozzle.

- Deep-fry and wash:After the plaster mold is removed from the casting machine, leave it for 10-30 minutes, and then fry it in cold water. The gold tree is removed after the gypsum is exploded due to shrinkage. After the large gypsum attached is brushed with a steel brush, it is soaked in 30% hydrofluoric acid for 10 minutes, and the remaining gypsum is washed away until the surface of the gold tree is clean.

- Cut:Cut the jewelry from the golden tree along the bottom of the spout and let dry.

💡Die holding

Die holding:The mold is all carried out by hand, with a special calender pushed back and forth on the surface of the jewelry, which requires the exquisite skill and technique of the craftsman.

💡Stoning

Stoning:According to the jewelry design, the diamond or gemstone is hand-sorted, picked out the appropriate color, cut, size match, ready for setting.

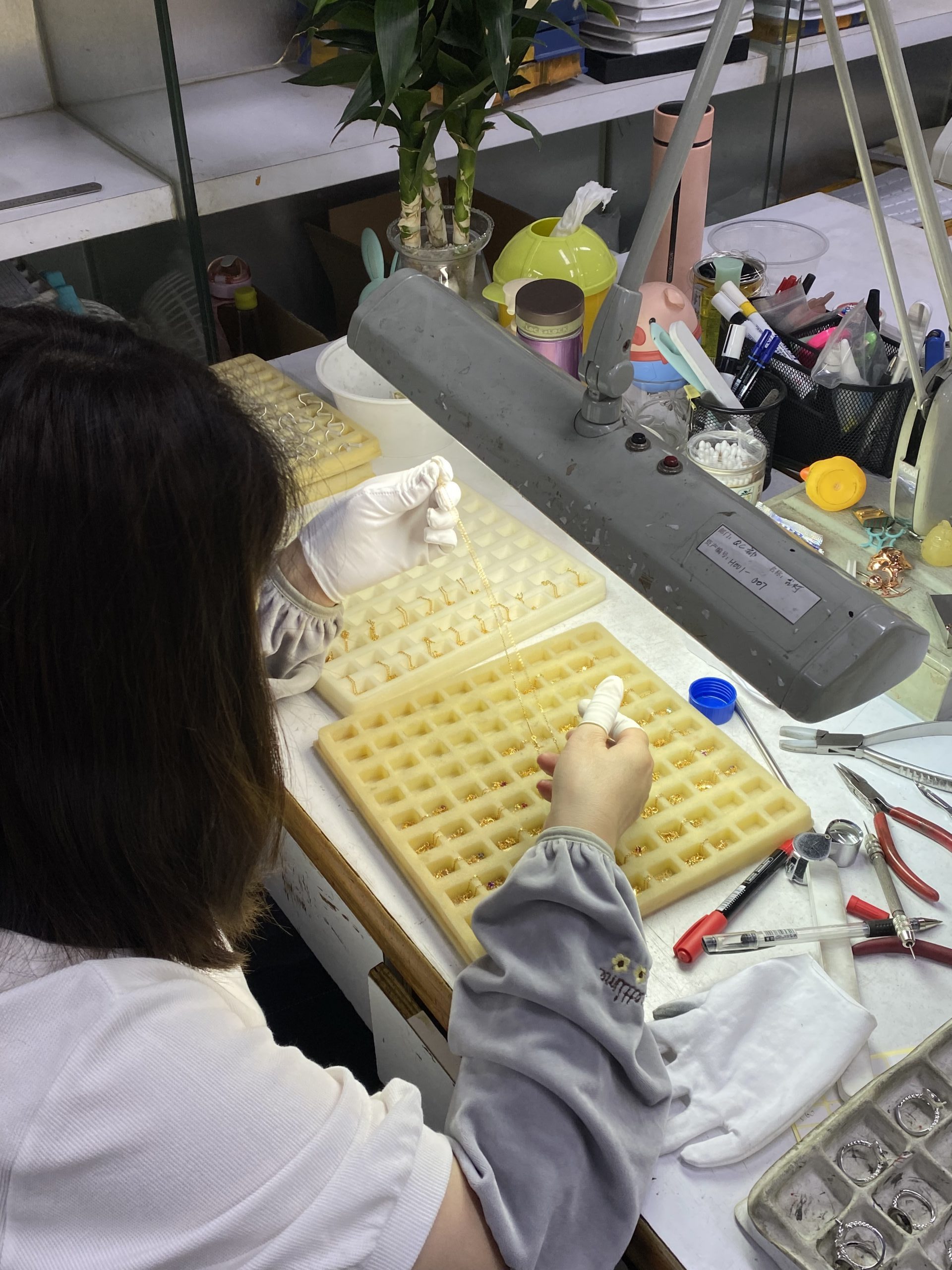

💡 Inlaid gemstone

Inlaid gemstone:Setting is a key part of jewelry making, and each diamond and gemstone needs to be set by hand.

If the design is simple, the setting is relatively easy, if the design involves a complex process or a large number of stones, the difficulty will be multiplied, and there is a risk of damage to the stone.

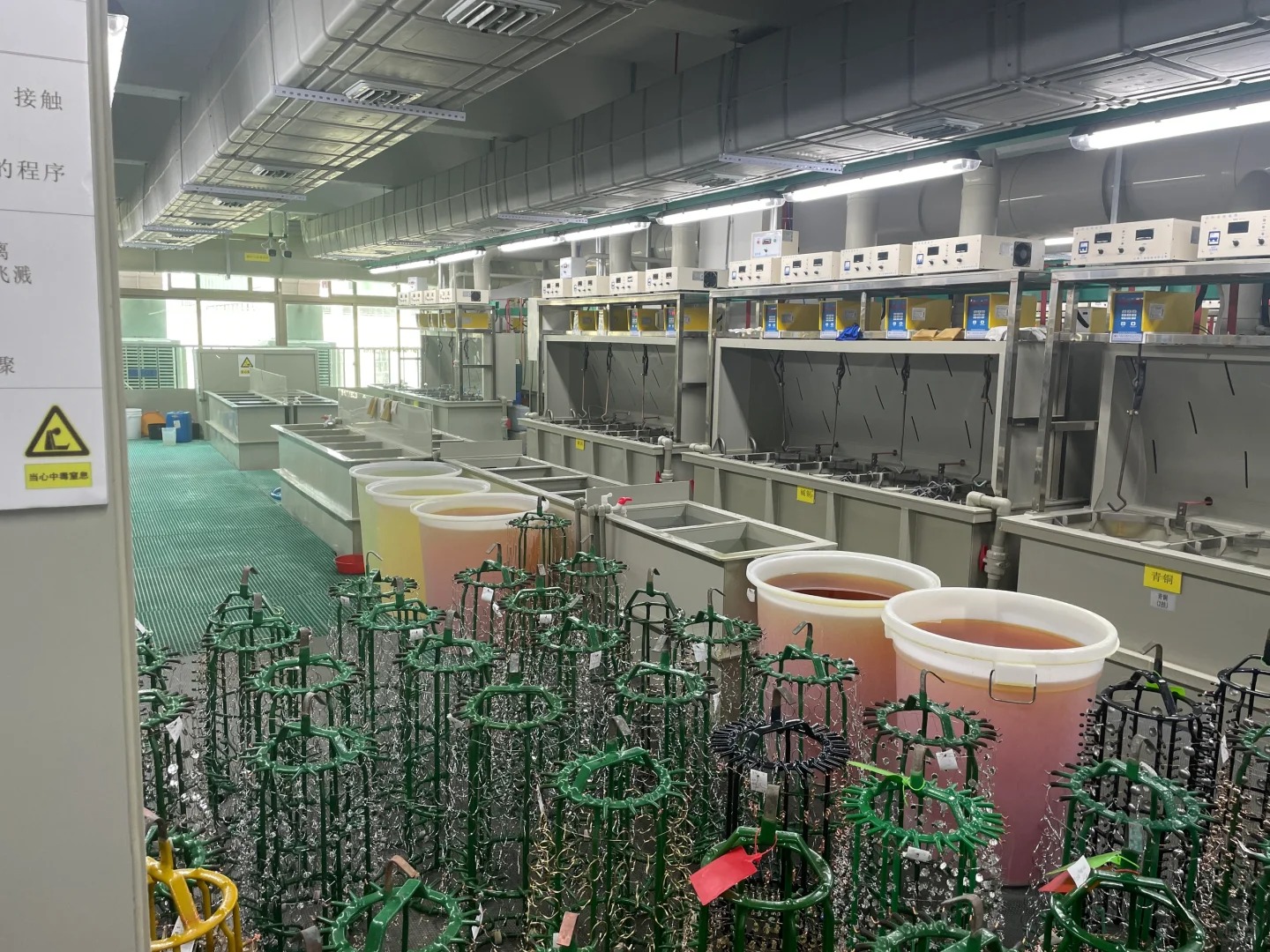

💡Polishing electrometal

Polishing electrometal:After the inlay is completed, the metal surface and details need to be polished, and some jewelry needs to be treated with electrical gold on the surface to make its surface more shiny and bright!

💡Quality Control

Quality Control:The finished jewelry should be inspected, and the unqualified jewelry should be returned to the previous process and remade. Qualified jewelry officially entered the market for sale.

Jewelry production has many processes, each process requires exquisite technology and time, so the general delivery time is 7-15 days.

📣📣📣As a jewelry source custom factory,we serves customers with exquisite technology and reasonable prices. The products have distinctive styles, high quality and favorable prices. We have complete, scientific and the most advanced technology and strict quality management system, the production and development capacity is in the leading position in the industry, and is the supplier of many brands at home and abroad.

Welcome to learn about our factory! And pay attention to us, take you to know more about jewelry knowledge ~